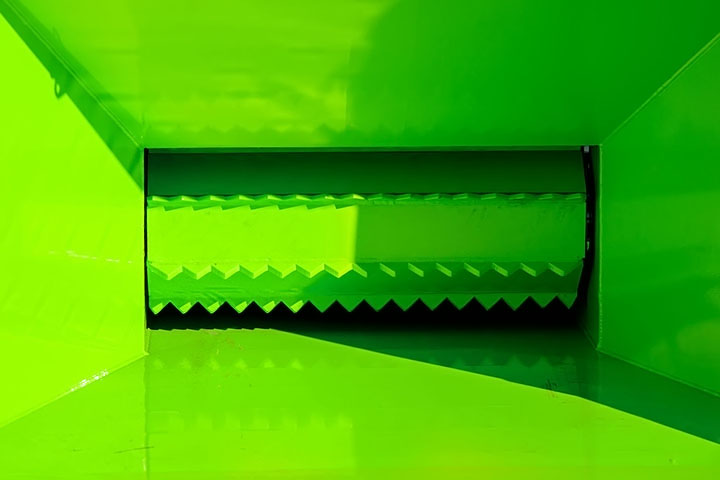

Extremely Wide Openings

When tree care professionals are asked about the size of opening they'd prefer, the answer is always the same -- as big as possible. The VORTEX® design allows the drum to be considerably wider, twice as wide in most cases, than drums that are currently on the market. Spanning the full width of a drum, the VORTEX® opening is nearly, in every case, twice as wide as all others in its class. The math is simple - the larger the opening, the more material can be placed into the chipper at one time for processing.

A Battle Of Widths

When limby trees or brush are compressed by a chipper's feed system, it will naturally tend to expand horizontally as it is weighted by the feed wheel (like a baker's rolling pin). Having a smaller, less-width, more square-shaped opening can create more contact, abrasion, and resistance during feeding as material is forced to rigidly compress horizontally by the left and right sidewalls of the opening in addition to vertically from the feed wheel. This can lead to more trimming and stoppages of workflow to reposition a branches. The VORTEX® design will always allow for much wider openings because its openings are not as limited proportionally by the maximum construction extents of a disc or drum size. Therefore, a wider spanning rectangular opening will be far more receptive to incoming material, allowing more volume to pass unimpeded through the opening and feed system en route to the cutting drum.

The opening of a VORTEX® chipper spans up to twice the width of all others in its class ... no restrictions due to drum size and disc weight constraints.

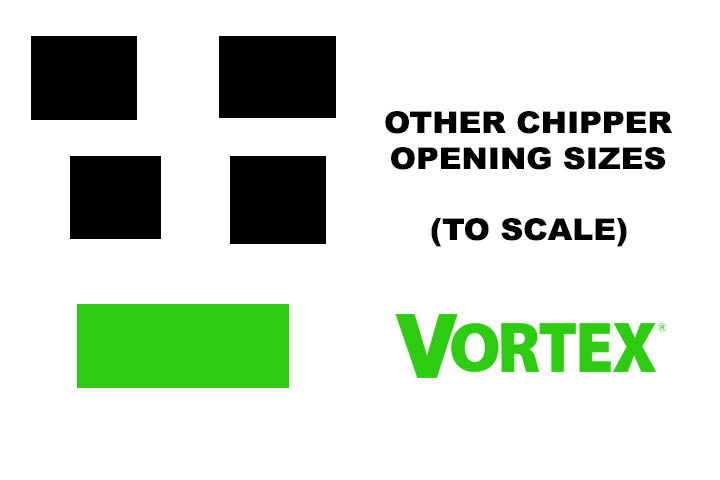

Squares and Inches

The tree care industry often recognizes chipper capacity as being classified by one standard linear measurement of the height of a chipper's feed opening (12", 15", 18"). However it is more revealing to use two dimensions instead of one in order to calculate the area of the opening to more accurately determine how much material volume the chipper can actually accept. One could refer to this as the target area for feeding. A wider opening offers more "space" for densely packed brush and limbs as they are funneled into the machine.

A comparison of various opening sizes from various chippers makes (drawn to scale). Which would you prefer to feed?