-

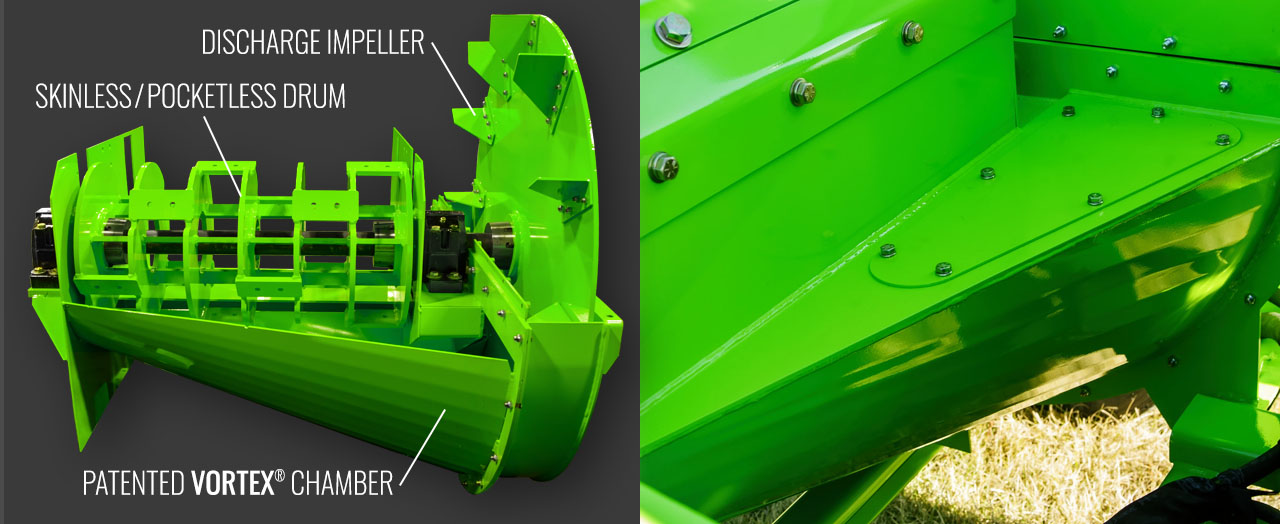

First Rate Production

VORTEX® brings the newest design technology that will deliver the optimum means of chipping brush.

-

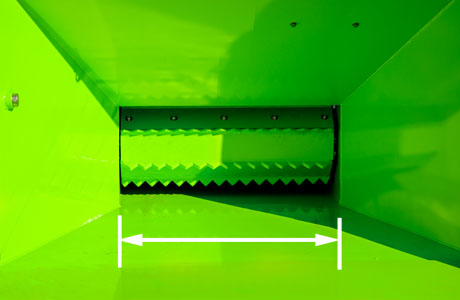

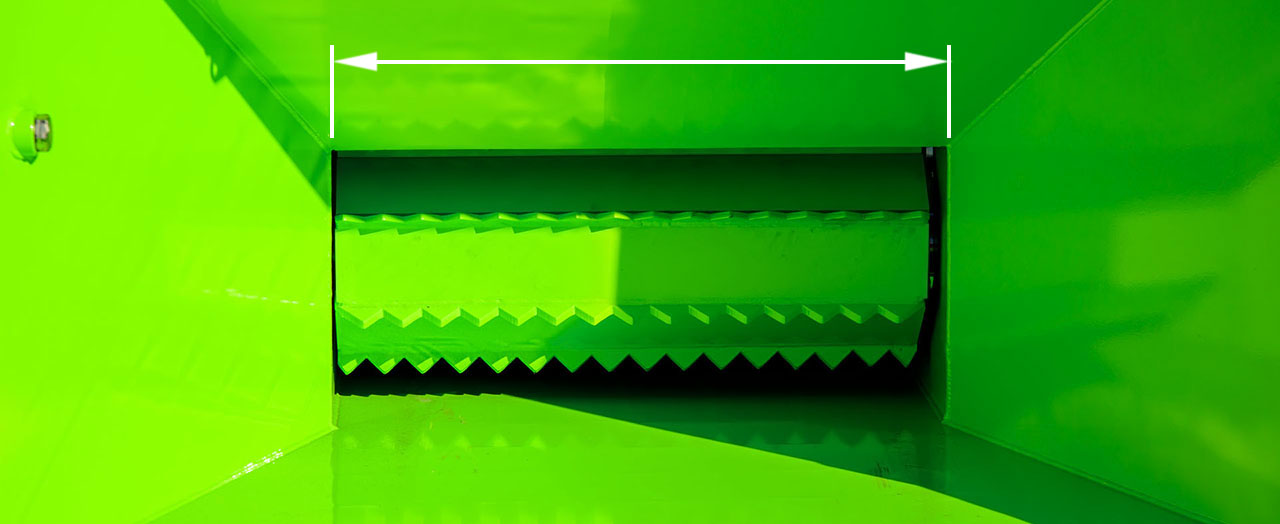

Hungry For More?

VORTEX® chippers have the widest openings in their class thus offering a larger target area for feeding and a wider angle of entry for incoming material.

-

Look For The Green

VORTEX® stands out with its highly visible and distinguishable fluorescent green color.

-

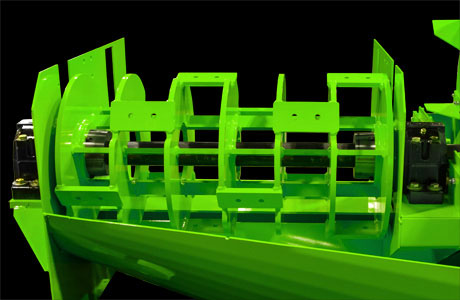

Patented VORTEX® Chamber

Makes it all possible to enjoy the best of worlds by cutting with a drum and throwing with a disc.

-

Chip Up A Storm

Process a wide variety of challenging materials with less trimming because of the unique VORTEX® design benefits.