More Info

Engine

Kohler 74 HP KDI Diesel or 133 HP PSI Gas

Cutting Drum

16″ diameter x 30″ long, open face, no pockets

Discharge Impeller

44″ diameter x 3/8″ thick

Feed Wheel

(1) 13″ diameter x 31″ wide, reverse pivot system

Throat Opening

31″ wide by 12″ high

Axle

7,000 lb. Torflex

Tires

ST235/80/R16 6-ply mounted on 8-bolt rim

Hitch

Pintle Ring

Paint

Painted with PPG safety fluorescent green

Weight

6,400 lbs

More Info

Engine

173 HP John Deere Diesel, 247 HP PSI Gas, 174 HP PSI Gas, 134 HP KDI Kohler Diesel Options.

Cutting Drum

30″ diameter x 32″ long, open face, no pockets

Discharge Impeller

44″ diameter x 3/8″ thick

Feed Wheel

(1) 24″ diameter x 31″ wide, reverse pivot system

Throat Opening

32″ wide by 18″ high

Axle

12,000 lb. Torflex

Tires

ST235/80/R16 6-ply mounted on 8-bolt rim

Hitch

Pintle Ring

Paint

Painted with PPG safety fluorescent green

Weight

9,500 lbs (Approx)

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

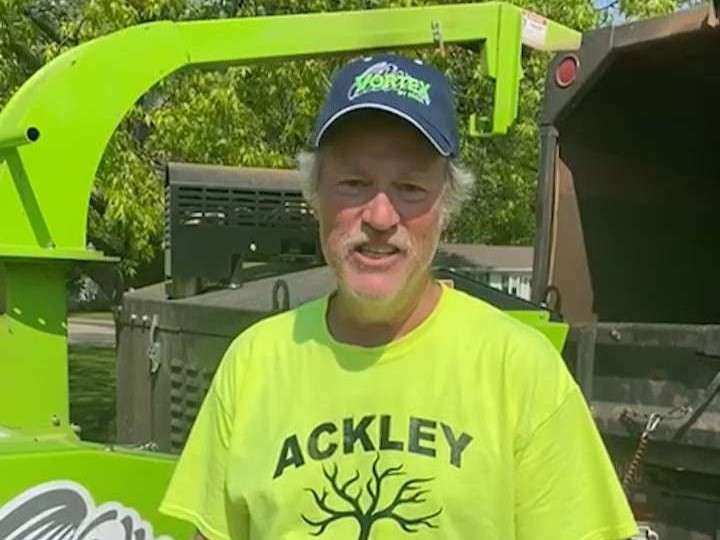

Our objective is “customer first” and along with industry best performance, we are committed to the utmost in quality and owner experience throughout the life of your machine. Our direct from the factory sales model allows customers to have immediate dialogue about markets, machines, and more. We have strategically placed service centers to handle normal repairs and maintenance and factory trained professionals to handle major services tasks. We use top quality components that are recognized throughout the industry and can support parts needs overnight when needed.

We aim to use the latest modern technology in all aspects of our business starting with the patented VORTEX® chipper design. Using precision engineering and physics, we have developed the most scientific and technologically advanced machines for the industry in over 40 years. We also use the latest technology in helping you, the customer, understand the inner workings of our machines. We use various technologies to help you through maintenance and service activities. All of this adds up to a positive, efficient, and profitable user experience. Our team has many years of wood chipper industry experience in engineering, marketing, manufacturing, and sales. We have seen and understand the challenges of finding the right machine design that offers an efficient, safe, and cost effective path to profit.

testing